Share:

More Articles

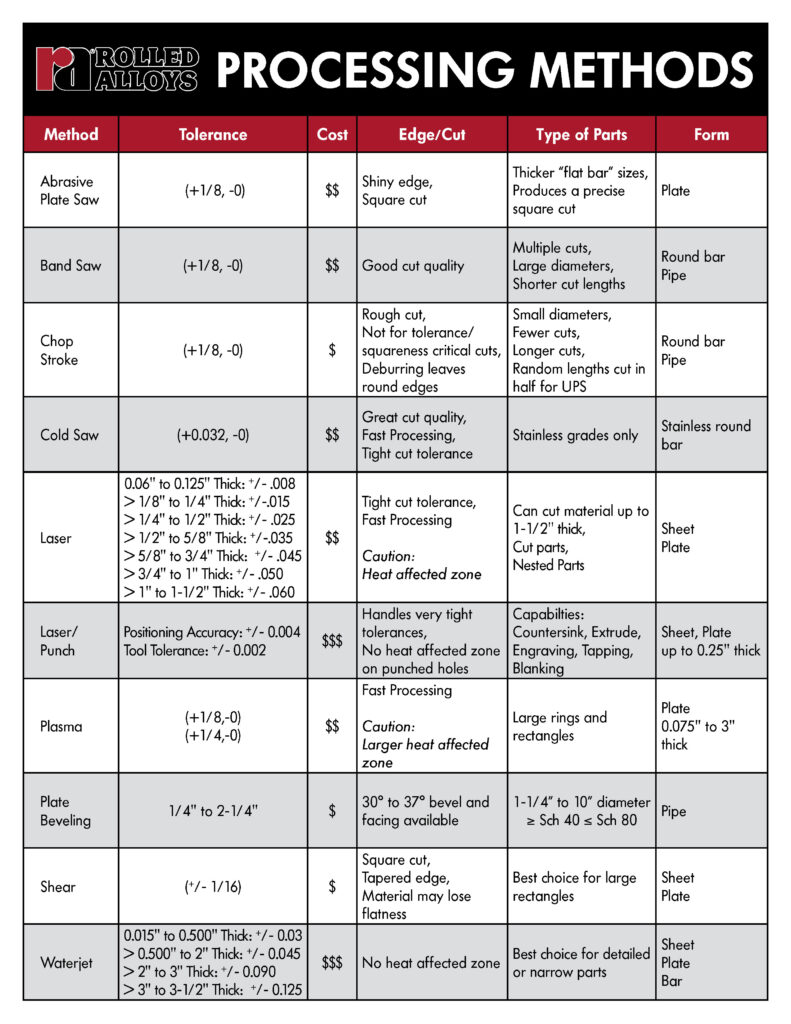

Which processing method is best for your needs?

Rolled Alloys strives to be a one stop shop for our customers by providing a variety of services and processing methods to the many industries we serve. With so many options, we understand that it can be hard to know for sure which processing method is best for you. We realize that it is easy to get in the habit of placing the same order for material you use often (hey, if it isn’t broke don’t fix it, right?).

So, we wanted to provide a resource that compares our processing methods to help you select the best cutting option for your price range. In the chart to the right, we have listed each of our processing methods along with the approximate tolerance, cost, edge/cut, type of parts (this does not mean that type of processing is limited to those parts, but these are parts that we know turn out well), and form.

This chart should make it easier when selecting a processing option for your next order, but please also keep in mind our large inventory of stock size and drop pieces.

To get an instant price, go to https://www.rolledalloys.com/cart. Rolled Alloys will continue to add new processing options to our facilities to ensure every customer is provided with the best quality processing and lead times in the industry! If you have any questions, our sales team is available in chat (found on our homepage) from 8am-8pm EST, or you can email onlinesales@rolledalloys.com.