NICKEL

Latest Articles

AL-6XN®

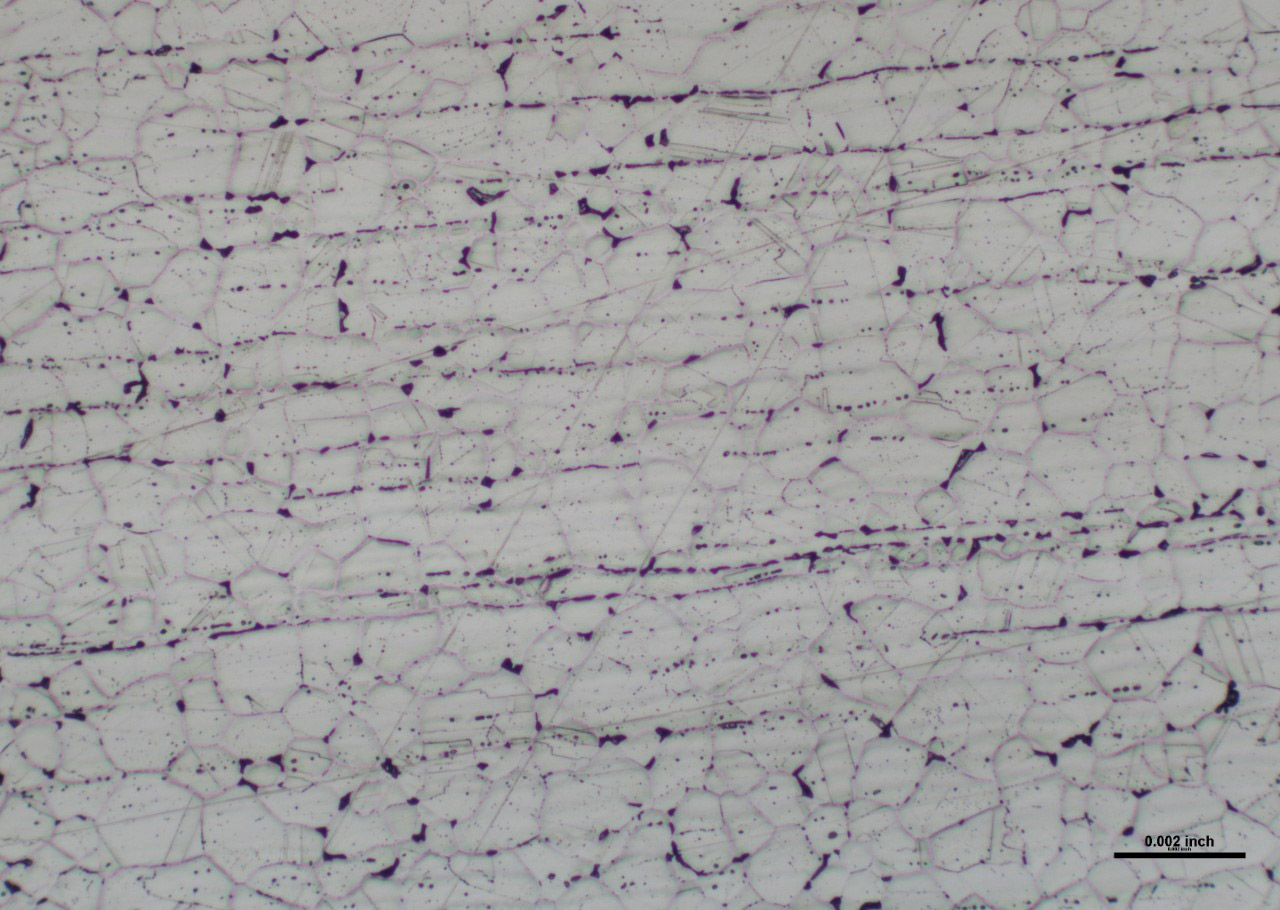

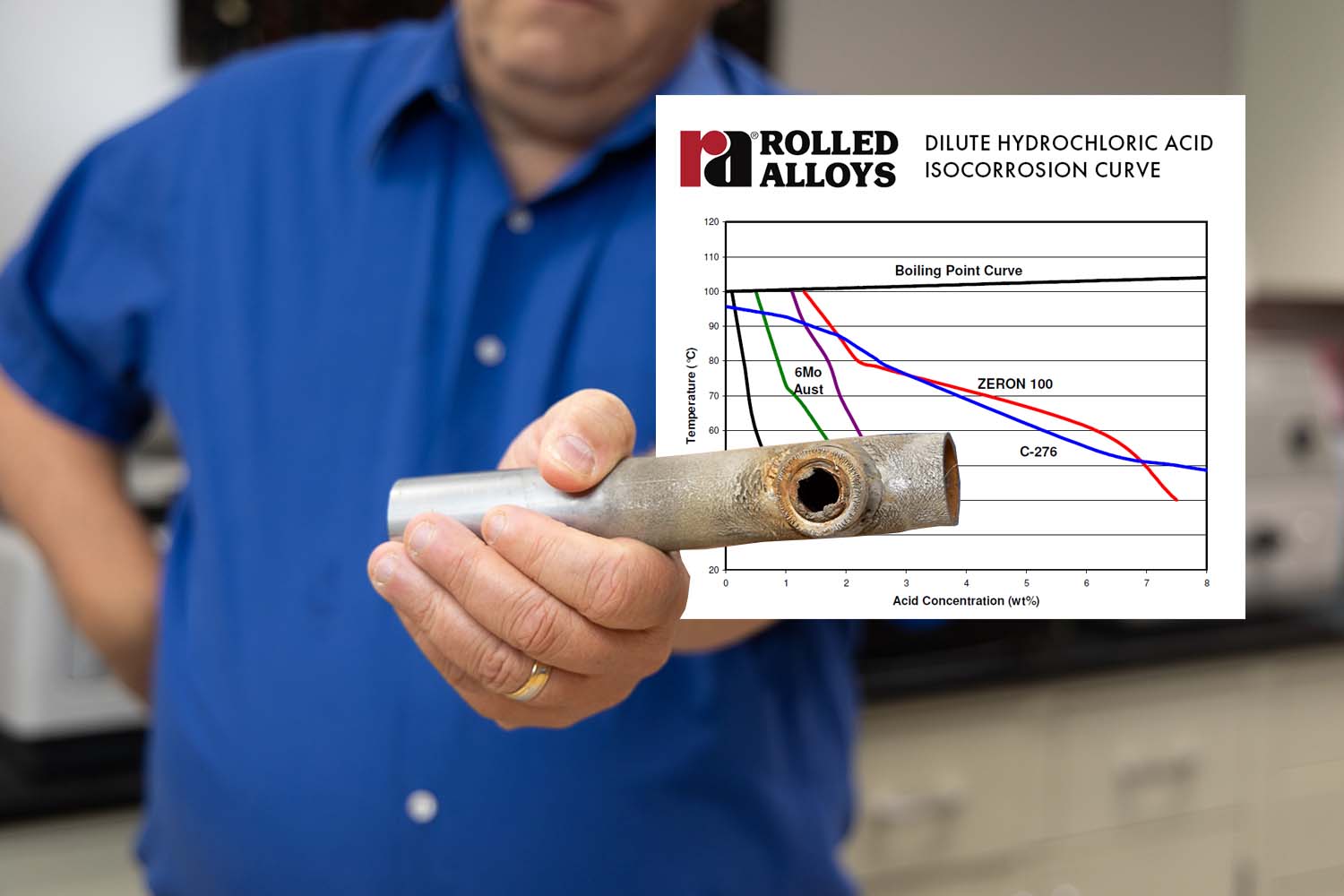

AL-6XN® alloy (UNS N08367) is a low carbon, high purity, nitrogen-bearing “super-austenitic” stainless alloy. The AL-6XN alloy was designed to be a seawater resistant material and has since been demonstrated to be resistant to a broad range of very corrosive environments. The high strength and corrosion resistance of the AL6XN alloy make it a better choice than the conventional duplex stainless steels and a cost effective alternative to more expensive nickel-base alloys where excellent formability, weldability, strength and corrosion resistance are essential.

The levels of chromium, molybdenum and nitrogen in AL-6XN all serve to provide resistance to acidic oxidizing chloride solutions previously achieved only by the nickel base alloys. High nickel (24%) and molybdenum (6.3%) contents make AL-6XN a solution to chloride ion stress corrosion cracking. Because of its nitrogen content, AL-6XN has greater tensile strength than common austenitic stainless, while retaining high ductility and impact strength. The ASME allowable stresses for AL-6XN are up to 75% higher than for 316L stainless, and more than twice those for the copper-nickel alloys.

- 6.3% molybdenum

- Over 25 years of proven seawater service

- Practical immunity to chloride stress cracking

- 50% stronger than stainless

- ASME coverage up to 800°F

- Easily welded

- Available in ALL product forms

AL-6XN® is a registered trademark of ATI Properties, LLC, a subsidiary of ATI Inc.

- Excellent resistance to pitting and crevice corrosion in chloride solutions

- Practical immunity to stress corrosion cracking in NaCl environments

- High strength and toughness

The levels of chromium, molybdenum and nitrogen in AL-6XN all serve to provide resistance to acidic oxidizing chloride solutions previously achieved only by the nickel base alloys. High nickel (24%) and molybdenum (6.3%) contents make AL-6XN a solution to chloride ion stress corrosion cracking. Because of its nitrogen content, AL-6XN has greater tensile strength than common austenitic stainlesses, while retaining high ductility and impact strength. The ASME allowable stresses for AL-6XN are up to 75% higher than for 316L stainless, and more than twice those for the copper-nickel alloys.

UNS: N08367

ASTM: B 688, A 240, B 675, A 312, B 676, A 249, B 804, B 691, A 479, B 462, A 182, B 564, B 366, B 472

ASME: SB 688, SA 240, SB 675, SA 312, SB 276, SA 249, SB 691, SA 479, SB 462, SA 182, SB 564, SB 366 CASE CODE N-438-3, B31.1 CASE 155-1

- FGD Scrubbers

- Reverse Osmosis

- Distillation Columns

- Offshore Oil and Gas

- Heat Exchangers

Share This Page