NICKEL

Latest Articles

RA 602 CA®

RA 602 CA® alloy is the most oxidation resistant/high strength nickel alloy available. It is capable of extreme temperature use up to and beyond 2200°F (1200°C). For thermal processing applications where minimal product contamination is necessary, the oxidation/scaling resistance of RA 602 CA is extremely desirable. A high chromium content, along with aluminum and yttrium additions, allows the alloy to develop a tightly adhering oxide scale.

A relatively high carbon content combined with the alloying additions of titanium and zirconium results in high creep rupture strength. RA 602 CA provides 150% of the strength of other commonly used nickel alloys such as alloy 600.

- Outstanding resistance to cyclic oxidation through 2250°F (1232°C)

- Excellent high temperature creep strength

- Resistant to carburizing and nitriding environments

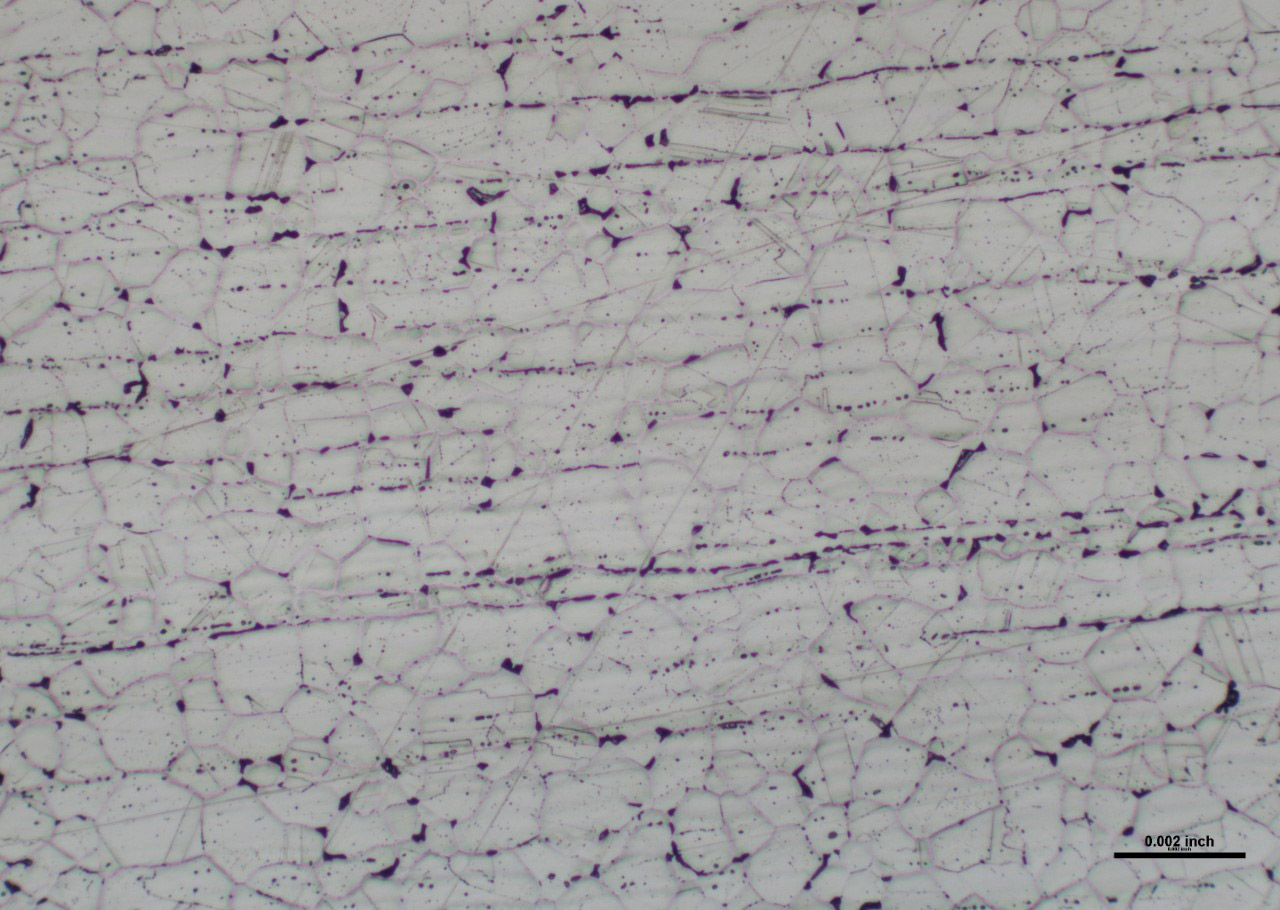

- Highly resistant to grain growth in service

- Superior behavior in oxidizing/chloridizing environments

- Good resistance to metal dusting

Plate, Weld Wire, Sheet

UNS: N06333

W. NR.: 2.4608

ASTM: B 718, B 719, B 722, B 723, B 726

AMS: 5593, 5717

- Tube supports in refineries and coal fired boilers

- Heat treating muffles, retorts, fan shafts and fixtures

- Carbon Fiber production muffles

- Sulfuric acid plant stack dampers

- Molten glass spinnerets

- Flare tips

- RA333 weld filler for repair welding of cast heat resistant alloys

- Tire Drop Chutes for Cement Kilns

Share This Page