STAINLESS STEEL

Latest Articles

17-4

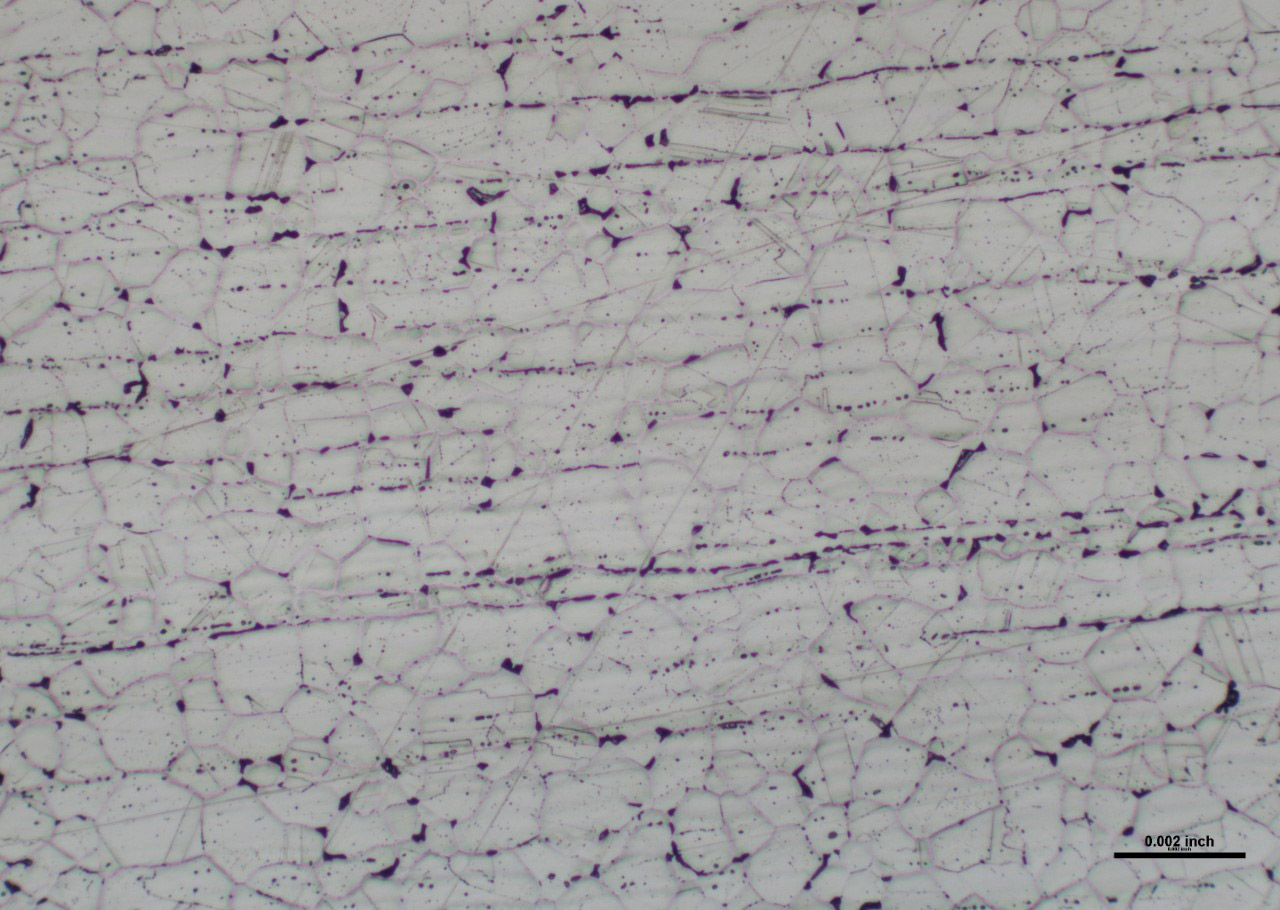

17-4 stainless is an age-hardening martensitic stainless combining high strength with the corrosion resistance of stainless steel. Hardening is achieved by a short-time, simple low-temperature treatment. Unlike conventional martensitic stainless steels, such as type 410, 17-4 is quite weldable. The strength, corrosion resistance and simplified fabrication can make 17-4 stainless a cost-effective replacement for high strength carbon steels as well as other stainless grades.

At the solution treating temperature, 1900°F, the metal is austenitic but undergoes transformation to a low-carbon martensitic structure during cooling to room temperature. This transformation is not complete until the temperature drops to 90°F. Subsequent heating to temperatures of 900-1150°F for one to four hours precipitation strengthens the alloy. This hardening treatment also tempers the martensitic structure, increasing ductility and toughness.

Rolled Alloys stocks 17-4 in condition “A”, and also stocks material in the hardened conditions H1150 and H1150D.

- High tensile strength and hardness to 600°F

- Corrosion resistant

- Excellent oxidation resistance to about 1100°F

- Creep-rupture strength to 900°F

Plate, Round Bar

UNS: S17400

W. NR.: 1.4548

ASTM: A 564, A 693, A 705, TYPE 630

ASME: SA 564, SA 693, SA 705, TYPE 630

AMS: 5604, 5643, 5825

NACE: MR0175

ISO: 15156

- Gate valves

- Chemical processing equipment

- Firearms production

- Pump shafts, gears, plungers

- Valve stems, balls, bushings, seats

- Fasteners

Share This Page